How to Choose DC Welder for Steel: A Comprehensive Guide

Jun. 15, 2024

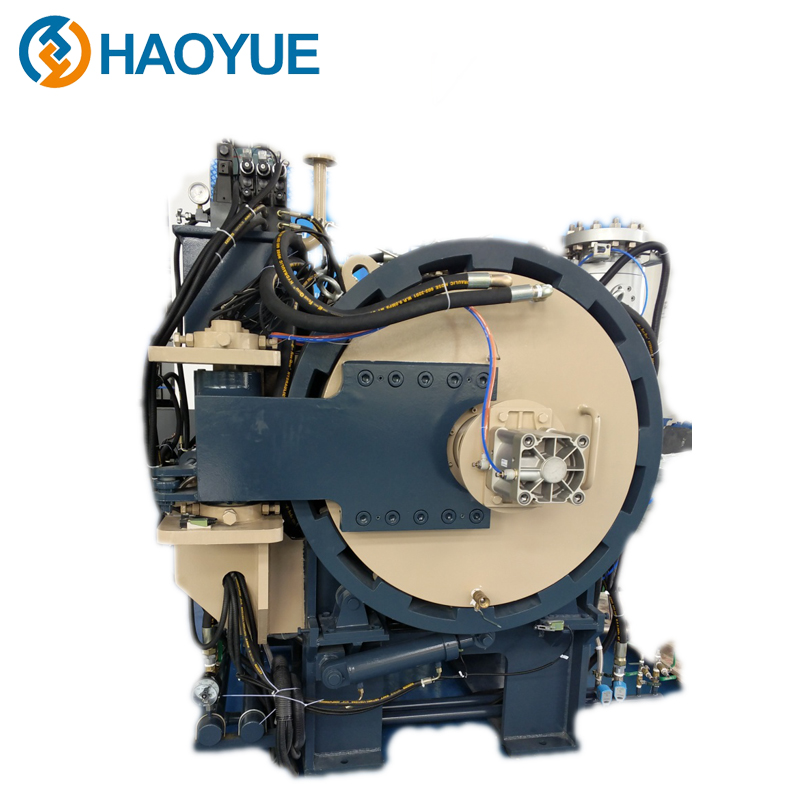

When choosing a DC welder for steelDC welder for steel, there are several important factors to consider to ensure you make the right choice. Follow these steps to select the best DC welder for your steel welding needs:

Step 1: Determine Your Welding Needs.

Before purchasing a DC welder, assess the type and thickness of steel you will be welding. Consider the required welding amperage and duty cycle for your specific projects.

Step 2: Research Different DC Welder Models.

Research different DC welder models on the market to find one that meets your welding needs. Compare features such as amperage range, duty cycle, and input power requirements to determine which welder is suitable for your steel welding applications.

Step 3: Consider Portability and Size.

If you need a portable welder for on-site projects, consider the size and weight of the DC welder. Choose a welder that is compact and lightweight for easy transportation.

Step 4: Check Power Input Requirements.

Ensure the DC welder you choose is compatible with the power supply available in your workshop or work site. Check the input voltage and amperage requirements of the welder to avoid any compatibility issues.

Step 5: Evaluate Welding Processes.

Recommended article:How Will Big Tube Laser Cutters Revolutionize Industries?

The Benefits of Using Different Types of CNC Laser Cutting Machines

The Benefits of Using a Customized Single Platform Fiber Laser Cutting Machine for Efficient Manufacturing

8000W Sheet Metal Laser Cutting Machine vs Traditional Cutting Methods

Key Questions to Consider When Investing in Large-Scale Laser Cutting Machines

How Do Large-Scale Laser Cutting Machines Work?

Q Switched Nd: YAG

Consider the welding processes you will be using with the DC welder. Some welders may be more suitable for specific welding processes such as stick welding or TIG welding. Choose a welder that is compatible with the processes you will be using.

Step 6: Review Welder Specifications.

Review the specifications of the DC welder, including its amperage range, duty cycle, and welding capabilities. Choose a welder with a sufficient amperage range and duty cycle for your steel welding projects.

Step 7: Consider Additional Features.

Look for additional features that may enhance your welding experience, such as voltage control, thermal overload protection, and adjustable arc force. These features can improve the quality of your welds and make the welding process more efficient.

Step 8: Set a Budget.

Establish a budget for your DC welder purchase and consider the cost of the welder, as well as any additional accessories or consumables you may need. Choose a welder that offers the best value for your budget.

By following these steps, you can confidently choose a DC welder for steel that meets your welding needs and helps you achieve high-quality welds on your steel projects.

Are you interested in learning more about MIG\MAG WELDER, dc welding? Contact us today to secure an expert consultation!

Recommended article:Radiation Detection and Survey Devices

How to use a fiber laser cutting machine?

Which welding machine is best for home use?

Extrusion Blow Molding Machine: Overview and Function

What is the process of valve grinding?

Valve Lapping Machine: Precision and Efficiency in Valve Seating

A Comprehensive Comparison between Rotary Drilling Rigs and Percussion Drills

199

0

0

Related Articles

Comments

All Comments (0)