How does a Puff Snacks Extruding Machine work?

Before delving into the mechanics of the extruding machine, let's understand the essence of puff snacks. Puff snacks are beloved for their airy, crunchy texture and the ability to pack an explosion of flavor in every bite. These snacks are made using a combination of starches, flours, and seasonings, resulting in a delightful treat enjoyed by people of all ages.

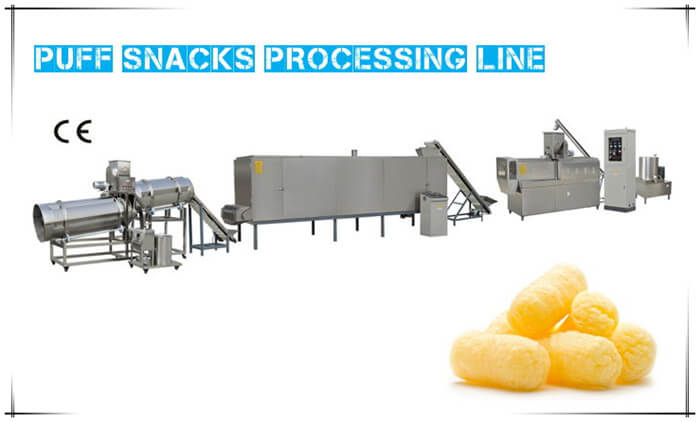

The Extrusion Process

Step 1: Mixing and Preconditioning

The journey of a puff snack begins with a carefully crafted mixture of ingredients. Starches, flours, water, and seasonings are combined to form a homogeneous blend. This mixture is then preconditioned, often involving heat and moisture, to create a dough-like consistency that is ready for extrusion.

Step 2: Extrusion

The star of the show is the puff snacks extruding machine. This sophisticated piece of equipment plays a pivotal role in shaping the dough mixture into the familiar puff snack forms. The extruder features a barrel with a screw-like structure inside. As the preconditioned mixture enters the barrel, it encounters high pressure and temperature.

The combination of pressure, heat, and mechanical shearing forces causes the starches to gelatinize and the dough to expand rapidly. The result is a transformation from a dense dough to a light and airy mass with a porous structure. This expansion creates the iconic puffiness of the snacks.

Step 3: Cutting and Shaping

As the expanded dough exits the extruder, it encounters cutting mechanisms that shape it into the desired forms. These can range from rings and curls to tubes and balls. The speed at which the extruded dough is cut contributes to the final texture and crunchiness of the snack.

Step 4: Drying

The freshly extruded puff snacks still contain residual moisture from the extrusion process. To achieve the desired crunchiness and shelf stability, the snacks undergo a drying phase. This can involve passing them through a drying tunnel or oven, where warm air removes moisture, leaving behind the desired crispy texture.

Step 5: Seasoning

No puff snack is complete without its signature flavor. After drying, the snacks are coated with a flavorful seasoning mixture. This can be a dry powder or an oil-based liquid that adheres to the snack's surface. The seasoning adds the taste that makes puff snacks so addictive.

Factors Influencing the Process

The extrusion process is a delicate balance of temperature, pressure, moisture content, and ingredient formulation. These factors influence the final texture, taste, and appearance of the puff snacks. Manufacturers fine-tune these variables to create consistent batches of snacks that meet consumer expectations.

In conclusion, the puff snacks extruding machine is a marvel of engineering that brings us the delightful crunchiness and flavor we associate with puff snacks. Through a combination of pressure, heat, and expertly controlled conditions, the machine transforms a simple mixture of ingredients into the airy, crispy treats we love to indulge in. The process is a testament to the fusion of science and culinary artistry, resulting in a snack that continues to capture our taste buds and imagination.

540

0

0

Comments

All Comments (0)