What are the classification of valve grinding machines?

Valve grinding machines can be classified based on various factors, including their design, operation, and intended applications. Here are common classifications of valve grinding machines:

Manual Valve Grinding Machines:

These are traditional valve grinding machines that require manual operation. The operator controls the grinding process, adjusting the angles, pressure, and other parameters by hand.

Automatic Valve Grinding Machines:

Automatic valve grinding machines are equipped with features for automated operation. They often include motorized controls, allowing for precise adjustments and automated grinding processes. CNC (Computer Numerical Control) technology may be incorporated for enhanced precision.

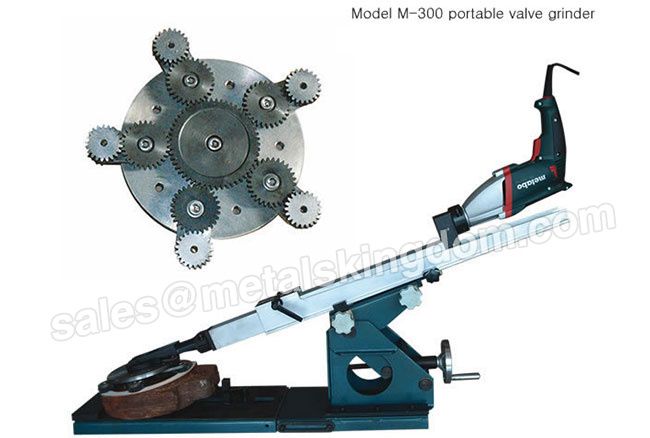

Portable Valve Grinding Machines:

Portable valve grinding machines are designed for on-site maintenance and repair tasks. They are compact and lightweight, allowing easy transportation to different locations. These machines are often used in situations where it is impractical to disassemble and transport large valves.

Stationary Valve Grinding Machines:

Stationary valve grinding machines are larger and more robust machines designed for use in workshops or manufacturing facilities. They provide a stable platform for grinding operations and are suitable for handling a variety of valve sizes and types.

Centerless Valve Grinding Machines:

Centerless grinding machines operate without a spindle or fixture to secure the valve. Instead, the valve is positioned between grinding wheels, which rotate in opposite directions. This design allows for continuous grinding, making it efficient for high-volume production.

Multi-Functional Valve Grinding Machines:

Some portable valve grinding machines are designed to perform multiple functions, such as grinding, lapping, and testing. These versatile machines offer a comprehensive solution for valve maintenance and repair.

Recommended article:Do whole house water filters remove limescale?

How To Maintain The Welding Positioner?

10 Questions You Should to Know about Nitrile Gloves Production Line

What is the use of stretch wrapping machine?

Guide to Automatic Riveting Machine

Top Trends in Automatic Wire Straightening: What You Need to Know for 2024

The Significance of Drill Pipe Thread Protectors

Wet and Dry Valve Grinding Machines:

Valve grinding machines can be categorized as wet or dry, depending on the lubrication and cooling methods employed during the grinding process. Wet grinding machines use a liquid coolant to reduce heat and friction, while dry grinding machines operate without the use of coolant.

Single-Purpose Valve Grinding Machines:

Some valve grinding machines are designed for specific applications, focusing on a particular type or size of valve. These machines are optimized for efficiency in a specific context, such as automotive or industrial valves.

High Precision Valve Grinding Machines:

High precision valve grinding machines are engineered for applications that demand exceptionally tight tolerances and surface finishes. These machines often incorporate advanced features and technologies to achieve superior grinding accuracy.

Economical Valve Grinding Machines:

Economical valve grinding machines are designed for cost-effective valve maintenance without compromising essential functionalities. These machines are suitable for smaller operations or budget-conscious users.

Specialized Valve Grinding Machines:

There are specialized valve grinding machines designed for specific industries or unique valve types. These machines may feature custom tooling or adaptations to meet specialized requirements.

Understanding the classification of valve grinding machines is essential for selecting the right equipment based on specific needs, applications, and operational preferences. Whether for routine maintenance, repair tasks, or high-precision manufacturing, the choice of a valve grinding machine depends on factors such as the scale of operations, valve types, and desired levels of automation.

What is the DTH method of drilling?

What are the different types of RC drilling rig?

What are aerial telescopic boom aerial work platforms used for?

Advantages of Sheet Metal Laser Cutting Machine

What is the difference between induction motor and slip ring motor?

Automated Screwdriving: The Pros and Cons

The Ultimate Buyer's Guide for Purchasing Bucking Machines

161

0

0

Previous: Where are vacuum furnaces used?

Related Articles

Comments

All Comments (0)