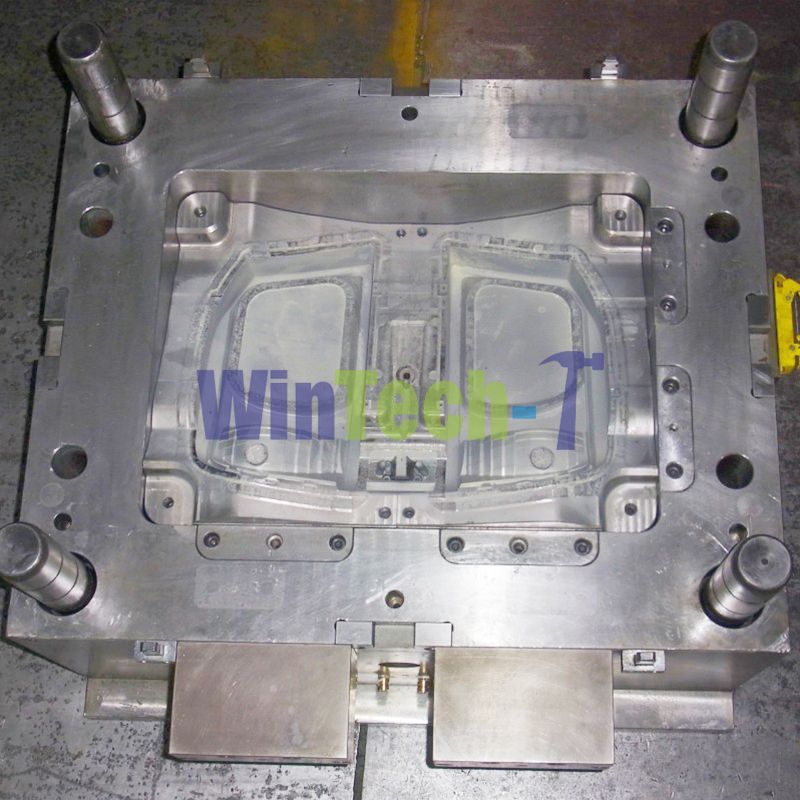

10 Questions You Should Know about Advantages and Disadvantages of Injection Molding

Jun. 25, 2024

Injection molding is a widely used manufacturing process for creating plastic parts and products. It involves injecting molten material into a mold, allowing it to cool and harden before being removed. While injection molding offers many advantages, there are also some disadvantages associated with this method. If you are considering using injection molding for your project, here are ten questions you should know about the advantages and disadvantages of this manufacturing process:

H2: What are the advantages of injection molding?

Precision and consistency: Injection molding allows for the production of complex and precise parts with a high level of accuracy. This method is ideal for creating components with intricate details and tight tolerances.

Efficiency and speed: Injection molding is a fast and efficient process, making it suitable for high-volume production. It can produce a large number of parts in a short amount of time, leading to cost savings and faster turnaround times.

Versatility: Injection molding can be used with a wide range of materials, including thermoplastics, thermosets, and elastomers. It is suitable for creating parts with varying sizes, shapes, and complexities.

Reduced waste: Injection molding generates minimal waste as any excess material can be recycled and reused. This not only makes the process more environmentally friendly but also helps to lower production costs.

H2: What are the disadvantages of injection molding?

High initial costs: Setting up an injection molding operation can be expensive due to the need for molds, machinery, and skilled labor. This initial investment may not be feasible for small-scale production or prototyping projects.

Long lead times: The design and fabrication of molds can take time, leading to longer lead times for production. Changes to the mold design can also prolong the process, potentially delaying product development and delivery.

Recommended article:What Are The Standards for Anchor Bolts?

How to Install Threaded Bar Anchors for Concrete?

What Are The Characteristics of A Striking Open Wrench?

What Are Carbide End Mills Used for?

Endless Round Slings vs. Chain Slings: Comparing Strength, Durability, and Flexibility

What Is the Difference Between Forged And Wrought Fittings?

Demystifying the Inner Workings of a Pneumatic Actuated Ball Valve

Limited flexibility: Injection molding is best suited for producing large quantities of identical parts. It may not be cost-effective for small production runs or projects that require frequent design changes.

Material limitations: While injection molding is compatible with a wide range of materials, some substances may not be suitable for this process. Certain materials may pose challenges in terms of molding, cooling, or ejecting from the mold.

H2: How can you mitigate the disadvantages of injection molding?

To address the high initial costs of injection molding, consider outsourcing the production to a contract manufacturer. This can help you avoid investing in expensive equipment and infrastructure while still benefiting from the advantages of injection molding.

To reduce lead times, work closely with your mold designer and manufacturer to optimize the design and fabrication process. Minimize design changes and communicate clearly to ensure that the molds are produced efficiently.

For projects that require flexibility, consider using 3D printing or other rapid prototyping methods to create initial prototypes and iterations. Once the design is finalized, you can transition to injection molding for mass production.

By understanding the advantages and disadvantages of injection moldingadvantages and disadvantages of injection molding and implementing strategies to mitigate potential drawbacks, you can make informed decisions for your manufacturing projects. Whether you are looking to produce high volumes of parts efficiently or create complex components with precision, injection molding offers a versatile solution for a wide range of applications.

Contact us today to learn more about how injection molding can benefit your specific project requirements.

Are you interested in learning more about 2k plastic mould price china, china 2k molding factories? Contact us today to secure an expert consultation!

Recommended article:What Are the Common Uses of Domed Nuts?

Choosing the Right Rubber Slurry Pump: A Comprehensive Buyer's Guide

The Science Behind Tri-cone Drilling Bits: How Do They Conquer the Earth's Depths?

Difference Between a Gate Valve And a Ball Valve

What Are the Common Uses of Thread Bars?

Comparing Belleville Disc Springs to Wave Washers for Spring Applications

Maximizing Efficiency and Precision: The High Pressure Control Valve

239

0

0

Related Articles

Comments

All Comments (0)