2K Molding vs Overmolding: Key Differences Explained

Aug. 03, 2024

WIT MOLD are exported all over the world and different industries with quality first. Our belief is to provide our customers with more and better high value-added products. Let's create a better future together.

**2K Molding vs Overmolding: Key Differences Explained**.

When it comes to advanced manufacturing techniques, two terms that frequently surface are 2K Molding and Overmolding. While both processes involve creating multi-material or multi-component parts, the nuances between them are substantial and significant for engineers and designers. Understanding these differences can be crucial for selecting the right process for your application. In this article, we'll delve into the key distinctions between 2K Molding and Overmolding, shedding light on their specific applications, benefits, and drawbacks.

### Understanding 2K Molding.

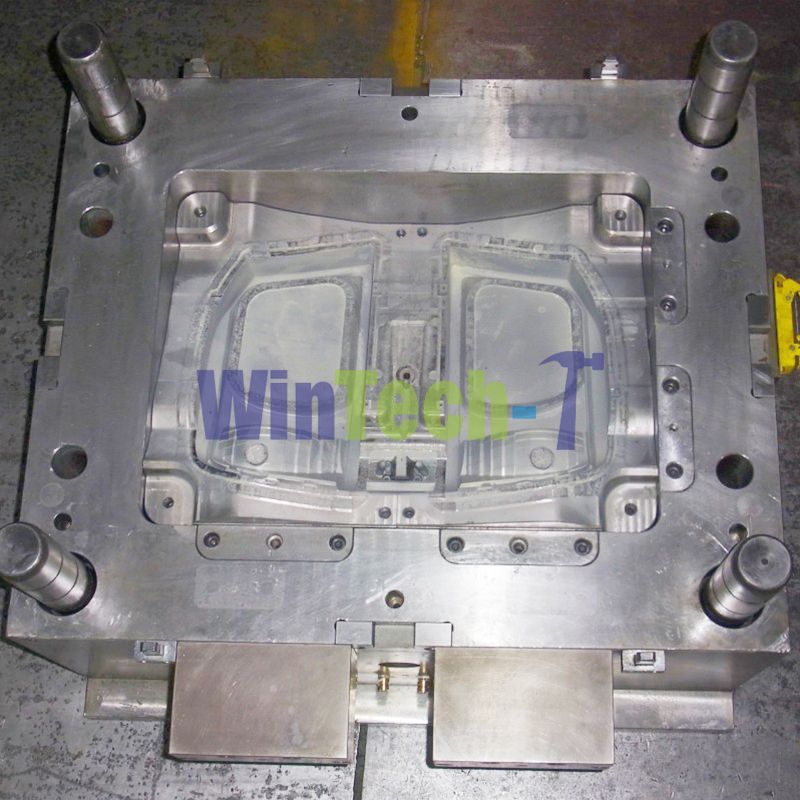

**Two-Component Injection Molding**, commonly referred to as 2K Molding, is a technique where two different materials are injected into the same mold during a single molding cycle. These materials can either be two different colors, types, or even consistencies, such as hard and soft plastics. The purpose of this technique is to create a single part with integrated multi-material properties, enhancing both functionality and aesthetics.

#### Key Characteristics of 2K Molding:

1. **Single Cycle Production:** The process is completed in one molding cycle, which means fewer operational steps.

2. **Integrated Design:** Resulting parts are a combination of materials, often bonded together at a molecular level, thus offering superior adhesion.

3. **Tooling Complexity:** Requires specialized and more complex molds, which can be a significant investment.

4. **Precision and Quality Control:** Highly precise, allowing for tighter tolerances and better consistency in manufacturing.

### Understanding Overmolding.

**Overmolding** is another multi-material molding technique but differs significantly in its approach. Overmolding is a two-step process where a base part, typically called the substrate, is first molded. This substrate is then placed into another mold where an additional material is injected over or around it.

#### Key Characteristics of Overmolding:

1. **Complex Assembly:** Involves multiple steps – creating the base part and then overmolding – making the process more intricate.

2. **Versatile Material Use:** Offers greater flexibility with the types of substrate materials and overmold materials that can be used.

3. **Bond Strength:** Depending on the materials, the bond between the two components can vary. It typically relies more on mechanical interlocking and surface adherence rather than molecular bonding.

4. **Application Specificity:** Commonly used for adding soft grips, seals, or aesthetic components like logos and ergonomic shapes onto a rigid body.

### Comparative Analysis: 2K Molding vs Overmolding.

To clearly distinguish between these advanced techniques, let’s break down their differences across crucial metrics:

Recommended article:Hexagon Metal Mesh: Applications and Benefits

What are the advantages of Belleville washers?

How are Titanium Tools Made?

What Are The Standards for Anchor Bolts?

How to Install Threaded Bar Anchors for Concrete?

What Are The Characteristics of A Striking Open Wrench?

What Are Carbide End Mills Used for?

1. **Production Efficiency:**.

- **2K Molding**: Inherently faster due to its single-cycle nature.

- **Overmolding**: Slower due to its multi-step process, which involves demolding and re-molding.

2. **Adhesion and Bonding:**.

- **2K Molding**: Superior bonding as materials are injected in one cycle, often resulting in molecular bonding.

- **Overmolding**: Relies more on mechanical bonds and surface adhesion, which may not be as strong.

3. **Design Flexibility:**.

- **2K Molding**: Limited by the need for complex, specialized molds.

- **Overmolding**: Offers greater design flexibility as it can combine diverse materials in a modular approach.

4. **Tooling Cost:**.

- **2K Molding**: Generally higher due to the complexity of the molds and machinery required.

- **Overmolding**: Can be more cost-effective, especially for small production runs or highly specific component designs.

5. **Application Suitability:**.

- **2K Molding**: Ideal for high-volume production of integrated parts needing high precision.

- **Overmolding**: Better suited for applications requiring custom features like soft grips, seals, or ergonomic enhancements on existing products.

### Conclusion.

Both 2K Molding and Overmolding offer unique benefits and are suited to different manufacturing needs. Choosing between them depends on multiple factors, including production volume, design complexity, material requirements, and cost considerations. By understanding the strengths and constraints of each process, manufacturers can make informed decisions, ensuring optimal product performance and cost-efficiency. Whether you're engineering a precision instrument or a user-friendly consumer product, mastering these techniques can provide the edge needed in competitive markets.

You can find more information on our web, so please take a look.

If you are looking for more details, kindly visit 2k molding vs overmolding.

Recommended article:Endless Round Slings vs. Chain Slings: Comparing Strength, Durability, and Flexibility

What Is the Difference Between Forged And Wrought Fittings?

Demystifying the Inner Workings of a Pneumatic Actuated Ball Valve

What Are the Common Uses of Domed Nuts?

Choosing the Right Rubber Slurry Pump: A Comprehensive Buyer's Guide

The Science Behind Tri-cone Drilling Bits: How Do They Conquer the Earth's Depths?

Difference Between a Gate Valve And a Ball Valve

202

0

0

Related Articles

Comments

All Comments (0)