How Automotive Injection Mold Improves Manufacturing Efficiency

Jul. 06, 2024

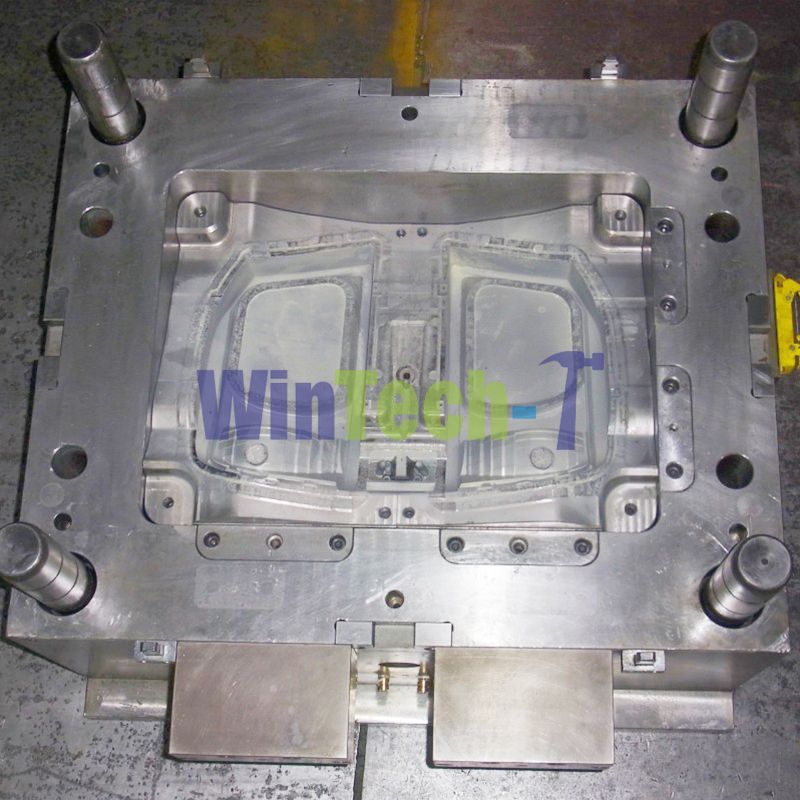

Automotive injection molding is a vital process in the manufacturing industry that has significantly improved manufacturing efficiency over the years. With advancements in technology and materials, automotive injection moldautomotive injection molding has become an essential tool in producing high-quality parts for the automotive industry. In this blog, we will explore how automotive injection molding improves manufacturing efficiency and why it is a crucial part of the manufacturing process.

One of the main advantages of automotive injection molding is its ability to produce complex shapes and intricate designs with high precision. With the use of computer-aided design (CAD) software and advanced molding techniques, manufacturers can create detailed parts that meet the exact specifications of the design. This level of precision is crucial in the automotive industry, where parts need to fit perfectly to ensure the safety and performance of the vehicle.

Another key benefit of automotive injection molding is its cost-effectiveness. By using molds that can be used repeatedly, manufacturers can produce a large number of parts in a short amount of time, reducing production costs and increasing efficiency. This is particularly important in the automotive industry, where high volumes of parts are needed to meet demand. Additionally, the use of automation and robotics in the injection molding process further reduces labor costs and increases productivity.

Furthermore, automotive injection molding allows for the use of a wide range of materials, including thermoplastics, thermosets, and elastomers. This flexibility in material selection enables manufacturers to choose the most suitable material for each part, ensuring optimal performance and durability. Additionally, the use of advanced materials with enhanced properties, such as high strength and heat resistance, allows for the production of parts that can withstand harsh environmental conditions and rigorous testing.

Recommended article:How Do Emotional Boundaries Work?

Unlock Precision: Micro Carbide End Mills for Small Holes

Hexagon Metal Mesh: Applications and Benefits

What are the advantages of Belleville washers?

How are Titanium Tools Made?

What Are The Standards for Anchor Bolts?

How to Install Threaded Bar Anchors for Concrete?

The speed of the automotive injection molding process is another significant factor that contributes to its efficiency. With cycle times ranging from a few seconds to a few minutes, manufacturers can produce parts quickly and consistently, leading to faster production times and shorter lead times. This rapid production allows manufacturers to meet tight deadlines and react quickly to changes in demand, making automotive injection molding a valuable tool for just-in-time manufacturing and lean production practices.

In addition to its efficiency, automotive injection molding also offers environmental benefits. By using recyclable materials and reducing waste through the use of precise molding techniques, manufacturers can minimize their environmental impact and contribute to a more sustainable manufacturing process. This eco-friendly approach not only benefits the environment but also helps companies meet regulatory requirements and improve their reputation as socially responsible businesses.

Overall, automotive injection molding plays a crucial role in improving manufacturing efficiency in the automotive industry. Through its precision, cost-effectiveness, material versatility, speed, and environmental benefits, automotive injection molding has become an indispensable tool for producing high-quality parts that meet the stringent requirements of the automotive industry. As technology continues to advance and new materials are developed, automotive injection molding will continue to evolve, further enhancing its capabilities and contributing to the success of the automotive manufacturing sector.

For more auto parts mould manufacturer, automotive mold made in chinainformation, please contact us. We will provide professional answers.

Recommended article:What Are The Characteristics of A Striking Open Wrench?

What Are Carbide End Mills Used for?

Endless Round Slings vs. Chain Slings: Comparing Strength, Durability, and Flexibility

What Is the Difference Between Forged And Wrought Fittings?

Demystifying the Inner Workings of a Pneumatic Actuated Ball Valve

What Are the Common Uses of Domed Nuts?

Choosing the Right Rubber Slurry Pump: A Comprehensive Buyer's Guide

231

0

0

Related Articles

Comments

All Comments (0)