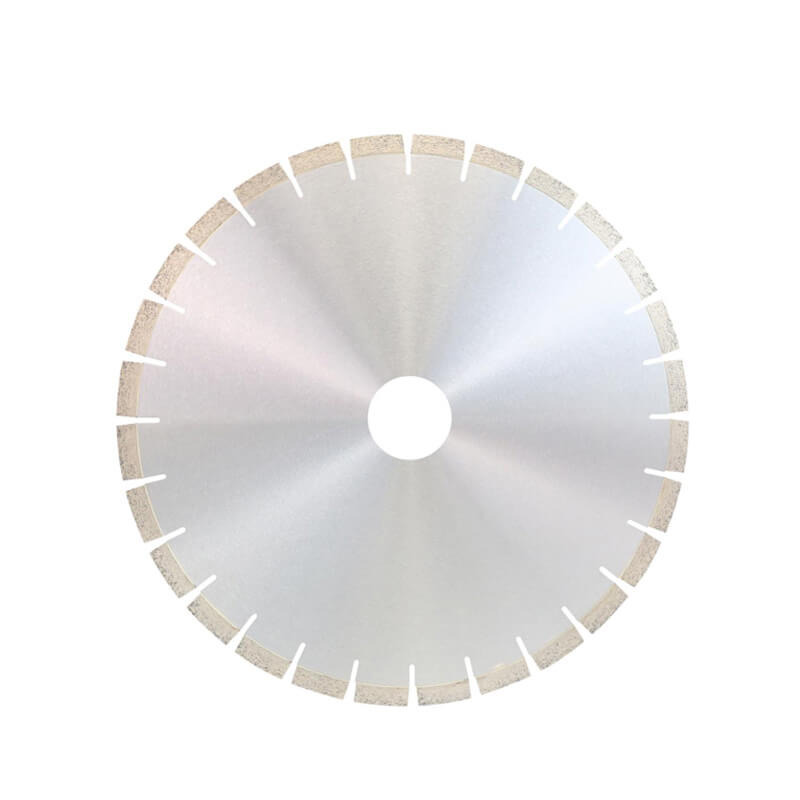

What Are Granite Cutting Discs Used For?

Granite cutting discs are specialized tools designed for the purpose of cutting granite, a dense and hard natural stone commonly used in construction, countertops, and various other applications. These cutting discs are essential in the stone processing industry and offer a precise and efficient way to shape, trim, or cut granite into desired forms. Here are some key uses of granite cutting discs:

Countertop Fabrication:

Granite is a popular choice for kitchen and bathroom countertops due to its durability and aesthetic appeal. Granite cutting discs are used to shape and cut granite slabs to the exact dimensions required for countertop installations.

Flooring Installation:

Granite tiles are commonly used for flooring in residential and commercial spaces. Cutting discs are employed to create precise cuts in granite tiles, allowing for accurate fitting during the installation process.

Monument and Sculpture Construction:

Granite is often used in the creation of monuments, statues, and sculptures due to its durability and ability to withstand weathering. Cutting discs are essential in shaping and detailing granite blocks or slabs to bring artistic designs to life.

Construction and Building Components:

Granite is utilized in various construction applications, including as structural elements, cladding, and architectural features. Cutting discs help in preparing granite pieces for these applications, ensuring they meet specific size and shape requirements.

Kitchen and Bathroom Fixtures:

Recommended article:How do I know if my saw blade is good?

What is better carbide or diamond blade?

Beryllium Copper Non-Sparking Hand Tools: An In-Depth Guide for Workplace Safety

Quick Change Tooling: Advantages and Considerations for CNC Magazine Systems

Case Studies in Oilfield Casing Success: Real-World Applications and Benefits

The Essential Guide to Mining Tools: Types, Uses, and Maintenance

What Is The Difference Between A Claw Hammer And A Split Hammer?

Granite cutting discs are employed in the fabrication of various granite fixtures such as sinks, backsplashes, and shower surrounds. The precise cutting ensures that these components fit seamlessly into their designated spaces.

Memorials and Headstones:

Granite is a popular material for memorial plaques, headstones, and grave markers due to its durability and ability to hold inscriptions. Cutting discs play a crucial role in shaping and engraving granite for these commemorative structures.

Custom Stonework:

In addition to standardized applications, cutting discs are used in custom stonework where specific shapes and designs are required. This could include unique architectural elements, intricate patterns, or customized granite pieces for special projects.

Repair and Restoration:

Granite cutting discs are also used in the repair and restoration of existing granite structures. Whether it's resizing a damaged countertop or replacing a damaged section of flooring, cutting discs allow for precision in restoring granite to its original form.

DIY Projects:

Homeowners and DIY enthusiasts often use granite cutting discs for personal projects that involve granite, such as crafting custom tables, garden features, or decorative pieces. These discs enable accurate cutting for various creative endeavors.

Granite cutting discs come in different sizes and specifications, and the choice of disc depends on factors such as the thickness of the granite, the type of cutting required, and the tool or machine being used. It's important to use the appropriate JK cutting disc to ensure clean and efficient cuts while preserving the integrity of the granite. Safety precautions, including the use of personal protective equipment, should always be followed when using cutting discs for granite or any other material.

Non-Sparking Tools in Oil and Gas: A Safer Choice

Take You To Know Valve Grinding Tools And Abrasives

How do I choose a cardan shaft?

CNC Tool Holders: What are They and What are the Different Types?

How to Use Diagonal Pliers?

Why are Non-sparking Sledge Hammers so expensive?

Everything You Need To Know About LED Commercial ...

470

0

0

Related Articles

Comments

All Comments (0)