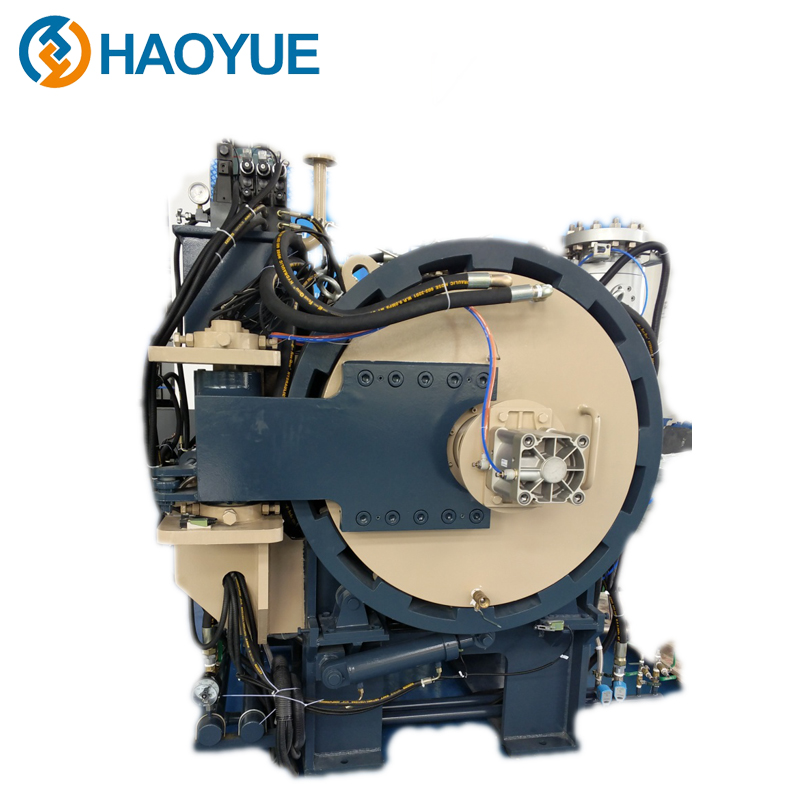

Revolutionizing Metalworking: Custom Melting Furnaces Unleashed

Jun. 04, 2024

Revolutionizing Metalworking: Custom Melting Furnaces Unleashed.

Custom melting furnaces are the latest innovation in the metalworking industry, offering unparalleled advantages for companies looking to enhance their production processes. These specialized furnaces are designed to meet the specific needs of individual businesses, allowing for more efficient and cost-effective melting of metals.

The development of custom melting furnaces has been driven by the increasing demand for precision and customization in metalworking. Traditional furnaces were limited in their capabilities, often leading to inconsistencies in melting temperatures and inefficient use of energy. Custom melting furnaces, on the other hand, are tailored to the exact specifications of each customer, ensuring precise control over melting conditions and optimal performance.

Recommended article:How Does Sustainable Farming Impact Our Environment?

Review: Battery Spot Welders, Why You Should Buy A ...

How to Choose The Best Boilers for Heating System

How to Choose Stainless Steel Tanks for Sale Used?

What to Know About Used Stainless Steel Tanks

10 Questions You Should Know about Solar Panel Installation Techniques

How to Choose a Buckwheat Processing Machine?

One of the key advancements in custom melting furnaces is the integration of advanced technology, such as computerized controls and automated systems. These features allow for real-time monitoring of melting processes, as well as the ability to adjust settings remotely for maximum efficiency. As a result, companies can minimize waste, reduce production time, and improve overall quality of their metal products.

Furthermore, custom melting furnaces offer significant cost savings for companies in the long run. By optimizing the melting process and improving energy efficiency, businesses can reduce their operational costs and increase their profitability. In addition, the flexibility and versatility of custom melting furnaces enable companies to adapt to changing market demands and expand their product offerings.

Are you interested in learning more about custom lead melting furnace solution, lead furnace solution, copper smelting factory solution? Contact us today to secure an expert consultation!

Recommended article:Revolutionize Production: High-End Rotary Heat Press Explained

Revolutionize Your Workflow: High-End Rotary Heat Press Benefits

What is the process of valve grinding?

Valve Lapping Machine: Precision and Efficiency in Valve Seating

A Comprehensive Comparison between Rotary Drilling Rigs and Percussion Drills

How Does a Wire Straightener Work?

Advancing Precision and Power: The Dual Action Hydraulic Cylinder

254

0

0

Related Articles

Comments

All Comments (0)