Steel vs Concrete: Which Material Used in Railway Track

Jun. 15, 2024

Steel vs Concrete: Which Material Used in Railway TrackWhich Material Used in Railway Track.

When it comes to deciding between steel and concrete as materials for railway tracks, the clear answer is steel. Steel has been the preferred choice for railway tracks for many years due to its numerous advantages over concrete.

One of the main reasons steel is preferred over concrete for railway tracks is its flexibility. Steel rails can easily adapt to changes in temperature and terrain, making them ideal for long stretches of track. In contrast, concrete tracks are more rigid and prone to cracking under stress, which can lead to costly maintenance and repairs.

Another advantage of steel tracks is their durability. Steel is much more resistant to wear and tear compared to concrete, which means steel tracks have a longer lifespan and require less frequent replacement. This not only saves money in the long run but also reduces downtime for track maintenance and repairs.

Recommended article:Anvils-2 Advise on buying used blacksmith anvils

How Does titanium sheet for sale Work?

5 Reasons Why Your Business Needs Mica Powder for Building?

Quartz Silica Powder: Uses vs Benefits Explained!

How to Choose Mullite Sand for the Ceramic Industry

Why is brass clad steel Better?

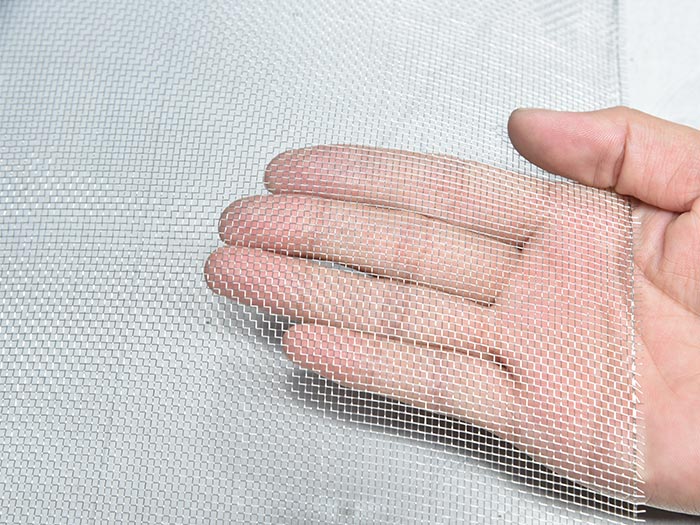

Exploring the Versatility and Applications of Metal Screen Mesh

In terms of maintenance, steel tracks also have the upper hand. Steel rails are easier to inspect and repair compared to concrete tracks, which can be more labor-intensive and time-consuming to maintain. This means that railways using steel tracks can operate more efficiently and minimize disruptions to train schedules.

Additionally, steel tracks are more versatile and can accommodate a wider range of train speeds and weights compared to concrete tracks. This flexibility allows for greater operational efficiency and the ability to support high-speed trains and heavy freight trains.

Overall, the choice between steel and concrete for railway tracks ultimately comes down to cost-effectiveness, durability, and operational efficiency. Steel tracks have proven time and time again to be the superior choice due to their flexibility, durability, and ease of maintenance. By opting for steel tracks, railways can ensure smoother and more efficient operations, ultimately benefiting both passengers and freight transportation alike.

Are you interested in learning more about H-Beam Rail Supplier, 38 Kg Rail? Contact us today to secure an expert consultation!

Recommended article:The Significance of Gray Iron Castings Across Industries

The Advantages of Color Coated Corrugated Steel Plates

Exploring the Versatility and Benefits of Hinge Joint Fences

Electrifying Safety and Efficiency: The Electric Fence System Unveiled

Applications of Stainless Steel Wire Mesh

Grey Iron Casting for Machinery and Equipment: Strength and Durability

Advantages and Applications of Hot Rolled Steel Coils

246

0

0

Related Articles

Comments

All Comments (0)