The Benefits of Using Foam Moulding

Sep. 06, 2024

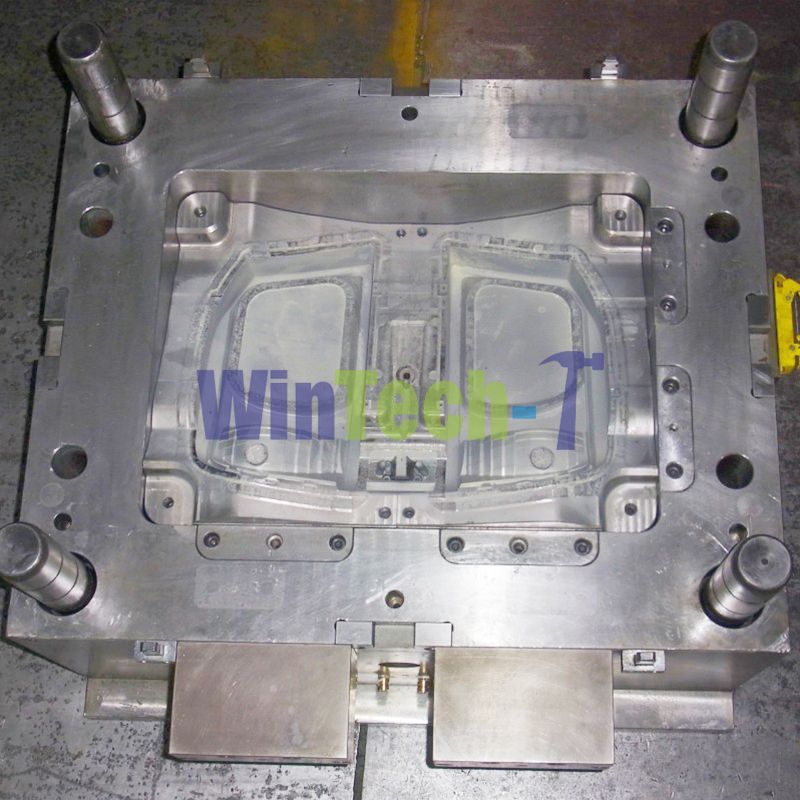

Foam moulding has transformed various industries by providing a lightweight, versatile, and cost-effective solution for countless applications. From architecture to packaging, understanding the benefits of foam moulding can empower consumers and manufacturers alike to make more informed decisions. Let's dive into the myriad advantages that foam moulding offers and explore why it has become a top choice across various sectors.

1. Lightweight and Easy to Handle

One of the most notable benefits of foam moulding is its lightweight nature. Materials such as expanded polystyrene (EPS) and polyurethane foam are considerably lighter than traditional moulding materials like wood or metal. This reduction in weight not only simplifies transportation and handling but also reduces shipping costs. In an era where efficiency is paramount, businesses are increasingly seeking ways to streamline their operations, and foam moulding answers that call effortlessly.

2. Versatile Applications

Foam moulding isn’t just for one industry; its versatility allows it to be used in various applications. In construction, it can be employed for insulation, whereas in packaging, it serves to protect delicate items during transit. The ability to be customized easily means foam moulding can meet specific requirements, making it suitable for everything from decorative architectural elements to complex industrial components. This adaptability is a testament to why foam moulding is rapidly becoming a go-to choice for designers and manufacturers.

3. Superior Insulation Properties

When it comes to insulation, foam moulding leads the pack. Materials like EPS provide outstanding thermal insulation, helping to regulate temperature and reduce energy costs significantly. In the construction industry, buildings that utilize foam insulation can lead to lower heating and cooling expenses, offering long-term savings to property owners. Additionally, foam moulding is resistant to moisture and does not support microbial growth, making it an ideal choice for various environments.

4. Cost-Effectiveness

In today's competitive marketplace, cost can make or break a project. Foam moulding presents a cost-effective alternative to traditional moulding methods. The reduced weight translates to lower shipping costs, while the efficient manufacturing processes associated with foam moulding minimize production timelines. Furthermore, lower labor costs can be achieved due to the ease of handling and installation. Balancing quality and cost is crucial for any business, and foam moulding strikes a perfect compromise.

5. Eco-Friendly Options

In a world increasingly focused on sustainability, foam moulding does not fall behind. Many manufacturers offer eco-friendly options, such as recyclable and biodegradable foams. Furthermore, because foam provides superior insulation, buildings constructed with foam-moulded materials can contribute to lower overall energy consumption, reducing their carbon footprint. Companies that opt for environmentally friendly materials not only position themselves favorably with consumers but also play a crucial role in promoting sustainable practices within their industries.

Recommended article:How to Master Form Moulding Techniques?

How to Choose the Best Molybdenum Wire Mesh Exporter?

How to Choose a Reliable Molybdenum Wire Mesh Exporter

What To Know About Gabion Walls

Top 10 Wire Mesh Manufacturers in China

How do you reform brush tips?

How to Select the Right Industrial Disc Brush Exporter?

6. Aesthetic Appeal

Beyond functionality, foam moulding can also serve a decorative purpose. Custom shapes and designs can enhance the aesthetic appeal of a project, whether it’s a residential home, commercial building, or an artistic installation. The ability to easily shape and paint foam means that designers can achieve their vision without the constraints imposed by other materials. This creative flexibility ensures that aesthetic qualities do not suffer for the sake of practicality, proving that foam moulding is a true win-win solution.

7. Sound Absorption

Another often-overlooked advantage of foam moulding is its sound absorption properties. The porous structure of foam can help reduce noise, making it a valuable material in residential and commercial settings alike. Whether it's an office looking to provide quieter environments for its employees or a homeowner wanting peace and tranquility, foam moulding can significantly contribute to sound reduction, enhancing the quality of life and work.

8. Enhanced Safety Features

Foam materials have inherent safety benefits. They are non-toxic and often fire-retardant, reducing the risk of fire hazards, particularly in construction applications. Moreover, the high impact resistance of foam also ensures that items remain protected during shipping and handling, further reducing the likelihood of accidents. When considering safety, especially in sectors such as child-oriented products or construction, foam moulding offers an invaluable edge.

9. Rapid Production and Scalability

The rapid production capabilities of foam moulding set it apart from other materials. The quick turnaround time allows for scalability; businesses can efficiently adapt to market demands without sacrificing quality. This agility is essential in today’s fast-paced economy, where consumer needs can change on a dime. Companies leveraging the benefits of foam moulding can maintain a competitive advantage by quickly responding to shifts in demand.

Conclusion

Foam moulding is more than just a modern trend; it’s a comprehensive solution designed to meet the multifaceted demands of today’s industries. From cost-effectiveness and versatility to safety and sustainability, the advantages of foam moulding are manifold. Whether you’re a business owner evaluating material options or a consumer curious about construction choices, understanding the myriad benefits of foam moulding is crucial. Embracing this innovative approach can elevate projects, enhance efficiency, and ultimately, foster a more sustainable future.

For more information, please visit form moulding, auto parts mold manufacturer, china injection mold parts manufacturers.

Recommended article:How Sustainable Practices Redefine Disc Brush Exporters?

ER308L vs Other Welding Wires for Structural Stainless Steel

2024 Guide to ER308L Welding Wire for Structural Stainless Steel

How Rotary Brushes Are Redefining Export Standards?

How to Select the Best Rotary Brush End Exporter?

4 Tips to Select ER308L Stainless Steel Wire for Thin Metal Welding

How Does ER4047 Aluminum Filler Rod for Brazing Work?

218

0

0

Related Articles

Comments

All Comments (0)